(honour me)

Our story so far

Making our own soap began as a home hobby to reduce plastic bottles in the bathroom! One teacher, one designer, we were both used to challenges but making a difference in a world inundated by unnecessary plastic seemed insurmountable. However, we persevered and now we offer a way to wash guilt-free and feel a little joy!

Our soap making process

Making good quality soap by hand is a process we have learned only with practice! Oname soaps are made with plant oils (with the exception of Palm), scented with essential oils and coloured with pigments and clays.

When we mix our plant oils (which are acids) with an alkaline base (we use Sodium Hydroxide) they react and neutralise into a salt which is your soap. This process is called Saponification. The natural reaction that takes place creates enough of its own heat to ‘saponify’ the oils so no external heat is needed. That’s why our method is called ‘Cold-process‘ soap making.

a unique approach

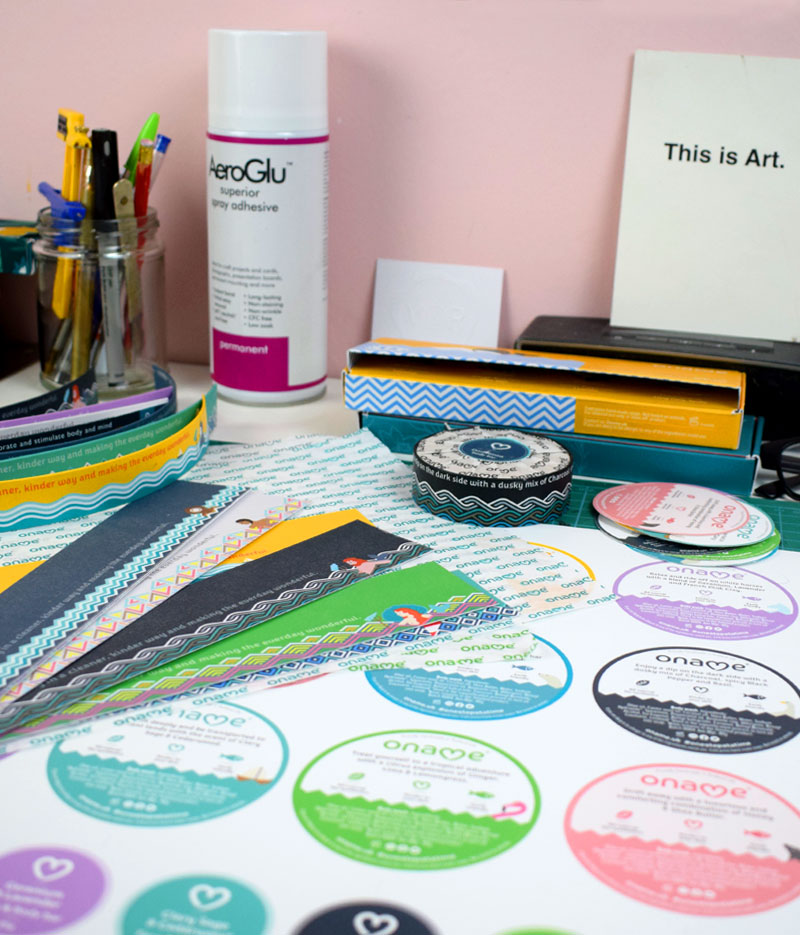

Customised to the last, we have designed our own soaping equipment so that we can make our circular soaps exactly the size we want. Tools out – we have built our own tippers (wooden wonders when it comes to pouring soap into molds) and designed our crazy molding racks to help us make small but healthy sized batches of soap to sell!

Small batch production

Measuring, mixing, stirring and pouring, cutting, racking, stamping and fitting; every step of our soap-making process is enthusiastically completed by hand. There’s a real sense of achievement in the completion of every batch.

Handmaking small batches of soap ensures good quality. We use oils that create softer soaps that have a shelf life so we prefer to small batch, ensuring sales and avoiding waste.

Cold process soap takes about a month to ‘cure’ or harden. During this time, the soaps are racked in a cool airy store before selling. It’s fresh soap only at the Oname Soapery!

our design journey

Colourful and fun, we created all of our design, illustration and packaging in house after endless imagining, trying and changing! Coming up with a fitting to hold a round cold process soap that needs to breathe has been our greatest triumph! Our fun illustrations are a nod to playfulness in life and a love of colour!

perfect little packages

Mermaids, divers, swimmers, seals, polar bears and white horses; there’s a story just waiting to be told in each of our soaps. Whether you buy them for yourself or as a gift, we hope each one helps you to express your plastic free ethos and commit to washing with joy!

© Oname Ltd. 2020. Registered in England Number: 12473215

Website by Youniverse